Energy saving

ABC implements the most energy saving solutions of the market.

Energy

saving

ABC stands out in the market for developing reliable energy saving solutions, being aware that 80% of the total cost of a compressor in 10 years comes from energy consumption. In order to reduce energy consumption to the maximum, ABC faces the market by providing solutions under the following characteristics.

In order to reduce energy consumption to the maximum, ABC faces the market by providing solutions under the following characteristics.

Main

features

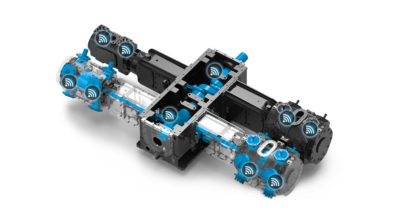

Horizontal configuration

The horizontal arrangement of our compressors makes the mm / sec of vibration at the time of compressing the minimum, making the mechanical wear of the machine also reduce to the maximum and offering a service cycle of 10,000 hours.

Double acting cylinders

Taking advantage of the linear speed of the rods generated by the crankshaft of the crankcase, we compress on both sides of the cylinder to take advantage of inertia and generate more compressed air with less energy, reducing at the same time the load losses and the temperature of the cylinders.

Direct coupling motor

We remove the belts from our previous ranges saving up to 5% in terms of energy efficiency, by directly coupling the motor to the compressor's flywheel, also avoiding the cyclic services of the belts.

Lower Delta T

The horizontal arrangement allows ABC to be equipped with the longest refrigerators on the market, making the difference between compressed air and water cooling it up to 5 °.

Regulation up to 80%

The frequency converter modulates the compressor so that the total absorbed power in the network is proportional to the compressed air that is produced for the plant, avoiding idling scenarios.

Heat recovery system

Through water outlet valves installed in the compressor's aftercoolers, we can grant to the plant 80°C water for instrumental use or any function that the customer wishes, by heating customer's water network through their heat exchangers.

-

CERTIFICACIONES

-

-