Compressors for BioGas plants: What are they and what are their peculiarities?

09/12/2024

Biogas is a renewable and green energy source that is produced from the decomposition of organic waste. This process not only reduces emissions of methane, a potent greenhouse gas, but also generates a renewable gas that can be used as a clean fuel. Our compressors are designed to increase the performance of biogas plants, ensuring reliable and efficient gas handling, supporting sustainable energy production and helping to mitigate climate change.

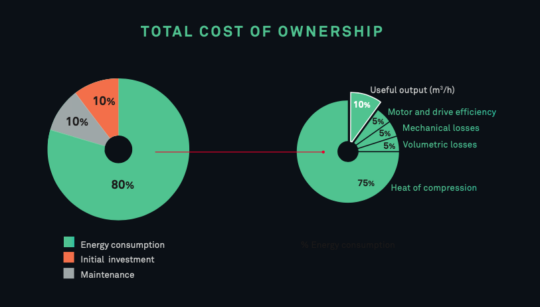

The compressor is one of the most important components in BioGas plants, and it is one of the components that has the most economic weight, both in OPEX (Operational Expenditure) and in CAPEX (Capital Expenditure). Also, because it is a critical element in the operation of the plant, therefore, it requires very high reliability and availability.

Within a BioGas plant, we can find different types of compressors. From BioGas compressors, prior to the upgrading (purification) process, through compressors for injecting biomethane into the network, and even CO2 compressors, for those systems that include the capture of this greenhouse gas. ABC has compression solutions for any of these cases.

Technology and innovation within reach of the client

There are many different technologies and designs for compressing gas, but ABC compressors have mechanical characteristics that make them unique in performance.

The design of horizontally opposed cylinders provides benefits such as substantially reducing compressor vibrations. Thanks to this, we can significantly increase the service cycle of our compressors, being able to operate the plant for 8,000 hours without any stoppage. Compared to other manufacturers, ABC stands out in this aspect, and we continue working on different R&D projects to offer a more reliable solution to our customers every day.

Another notable benefit of vibration reduction is the possibility of using a frequency converter without limitations. Our compressors do not have to avoid any frequency range, thus offering the largest regulation range on the market. This gives the compressor great versatility to meet the different demands of the plant.

Thanks to the technology developed by ABC our compressors are among the most efficient on the market. As we have noted previously, compressors are one of the largest sources of electrical consumption in BioGas plants, therefore, this efficiency is vital.

“We are aware of the economic weight that OPEX has in BioGas plants. At ABC we have the most reliable and efficient technology, being able to significantly reduce operating costs.” Alex Cuesta, Sales Area Manager BioGas and CO2.

Total Cost of Ownership in 10 years:

On the other hand, it is worth noting that ABC technology is 100% oil-free. This aspect is very important, taking into account that the purity of the gas is of vital importance in applications such as the injection of biomethane into the network, or the recovery of CO2 for use in the food sector.

Alex Cuesta, Sales Area Manager BioGas and CO2, emphasizes “right now we can say that being an oil-free compressor is a must in the market.”

Another important aspect to highlight is the standardization of the range. Although ABC has extensive experience manufacturing this type of compressors, the standardization of the ECOO (for CO2) and BIO (for BioGas and biomethane) ranges have provided great benefits in terms of reducing costs and production times. Thus being able to offer a much more competitive solution in the market.

Our vision for the future

The BioGas sector is growing a lot in recent years and there is a very great potential in this sector, and even more so taking into account the change in consciousness that people are having, which is why we are beginning to worry more about pollution and about using renewable gases or renewable energy sources in general. All of this is having an impact on this type of plants and is being seen in the number of plants that are built year after year. After all, it is a way to dispose of waste without decomposition gases being released into the air and polluting, and thus having a renewable gas.

Above all, we are seeing this trend of the rise of BioGas at the European level, derived mainly from the consequences of the war in Ukraine that has brought about the increase in the price of gas, so other ways to achieve it have been sought. Although, we are sure that sooner or later this boom will reach other continents as well.

Noticias

relacionadas

Jan

Maialen Corral, técnica en el Departamento de Personas: “Nuestro éxito no solo proviene de la tecnología, sino de todas las personas que formamos ABC”

Maialen Corral forma parte del Departamento de Personas de ABC desde el año 2017. En esta …

Nov

New app from Coca Cola Austria rewards consumers for recycling PET bottles

From next year, if Coca-Cola customers in Austria check-in at a collection container, scan a code …

Feb

Business R&D support programme – HYSHORE

-

CERTIFICACIONES

-

-